30. October 2024

Breathing new life into old wood is like preserving memories, crafting stories from timber that has seen many days. Each piece—whether a salvaged table or bed slat—carries its history, becoming something entirely new yet familiar. From rustic bottle holders to handcrafted ornaments, reclaimed wood turns the ordinary into art, woven with warmth and character. Though it takes patience to restore, the result is a piece rich with soul, echoing past lives while finding a new purpose in handmade beaut

02. October 2024

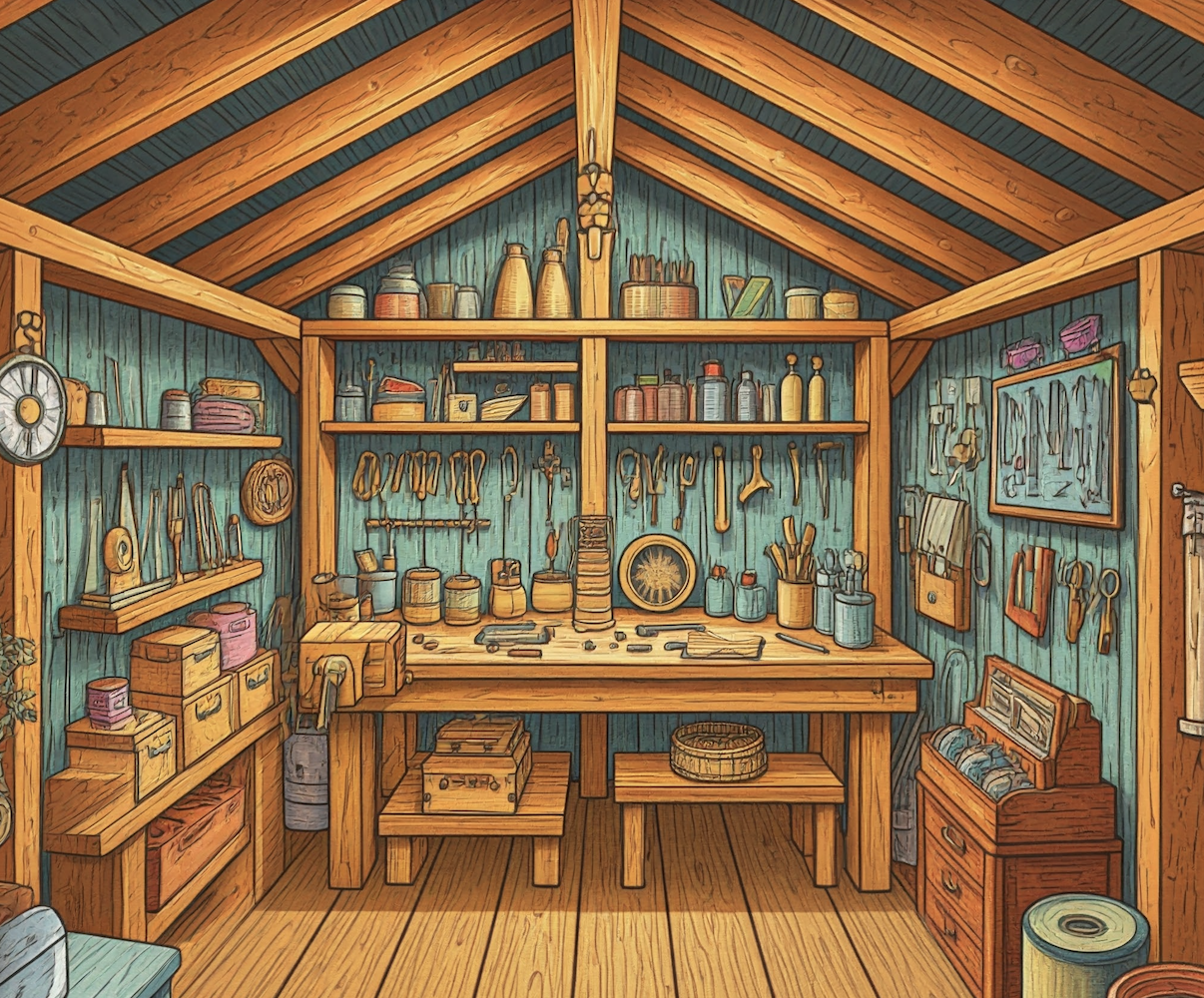

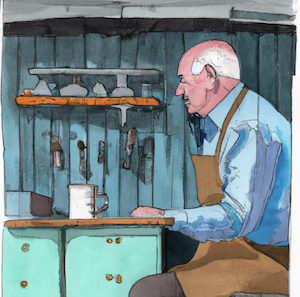

My 4m by 3m shed is a compact yet efficient space where every tool has its place. A large workbench, racks for hand tools, and labeled storage boxes keep everything organized. Most-used tools are easily accessible, while rarely-used items are stored away. I enjoy crafting storage solutions from scraps of wood, making use of every inch. Organizing the shed brings a sense of calm and fuels my creativity, turning it into a sanctuary where ideas come to life.

18. September 2024

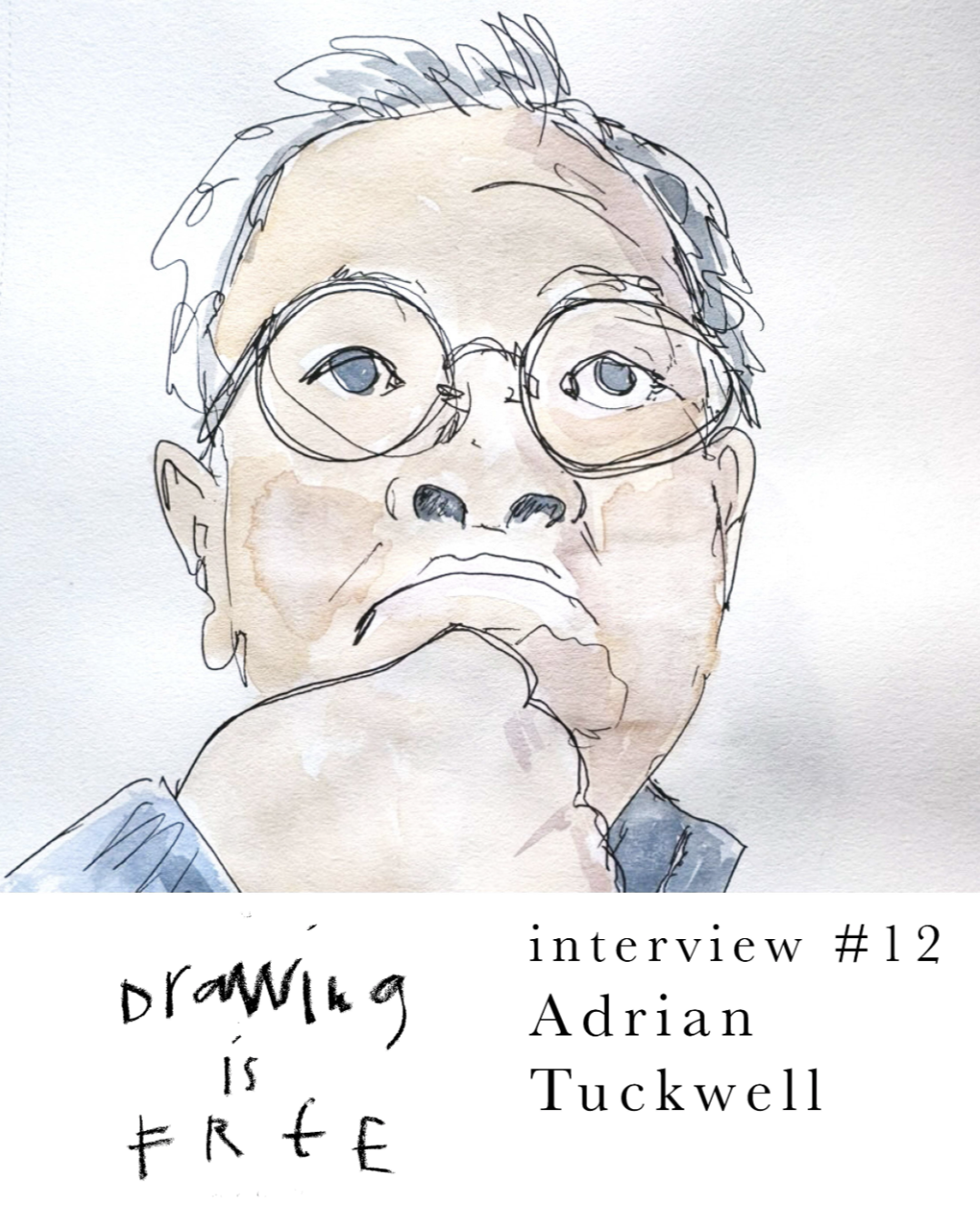

I recently did an interview with Chloe Briggs, host of the Drawing is Free Zoom group I’ve been part of for 18 months. Each Monday, we draw quick portraits to music, filling our sketchbooks with about 10-12 pieces in an hour. It’s fast, fun, and has really boosted my confidence in portrait drawing.

15. May 2024

After running my maker and artist website successfully for a decade, COVID-19 derailed my motivation and disrupted my participation in craft fairs. The pandemic's impact left me creatively stalled, but as normalcy returns, I'm working to rekindle my passion. To regain motivation, I'm focusing on small, achievable goals, reestablishing routines, seeking inspiration from the community, practising self-care, and setting future craft fair dates. Join me on this journey back to creativity.

01. May 2024

Discovering solace amidst the chaos of construction, I retreated to my garden's megaden, armed with firewood and a flask. Surrounded by nature, warmth, and eclectic trinkets, I found unexpected tranquility. Despite being tethered to technology, the symphony of the outdoors fostered clarity and creativity. Reluctantly leaving, I departed with a renewed appreciation for the healing power of nature.

17. April 2024

Dive into the delightful world of miniature marvels as I share my journey of crafting wonky watercolour houses. From sketching whimsical outlines to breathing life into vibrant scenes, discover the joy and tranquility found in each stroke of the brush. Join me on this creative adventure where imagination knows no bounds.

04. October 2023

In woodworking, as an amateur in a small space, choose projects that excite and challenge you, learn new techniques, and gradually raise complexity. Embrace space constraints as opportunities for creativity, and don't fear mistakes—they're lessons. Keep the passion alive through the journey of improvement.

07. September 2023

Tools are my constant companions in the world of craftsmanship. From my garage to my shed, house, and everyday carry, they save me time and money while enabling me to turn dreams into tangible achievements.

11. August 2023

Discover the joy of crafting as we explore the delight of transforming wood and metal into intricate shapes, celebrating vibrant colors, relishing the touch of smooth finishes, and creating lasting memories through shared moments of creativity. Handmade treasures are more than objects; they are conduits of joy that enrich our lives and connect us with others.

03. August 2023

Woodworking brings therapeutic benefits of mindfulness, joy, and patience. Embracing imperfections and learning from mistakes, it fosters self-discovery and creates a supportive community. A meditative escape from the digital world, it nurtures creativity and transforms lives.